Computertomography at Siroma-Plast

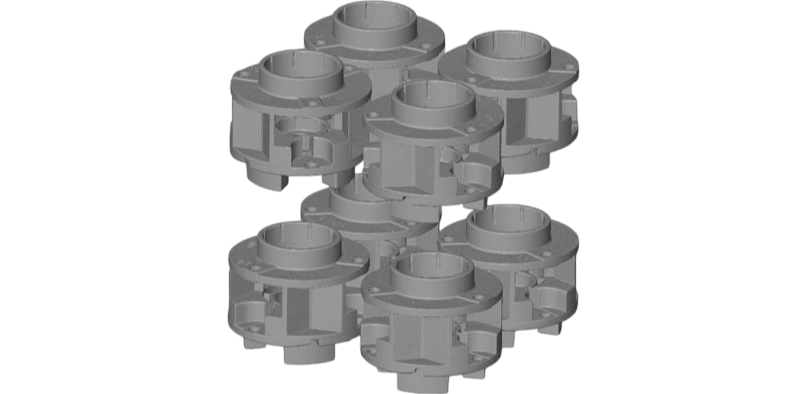

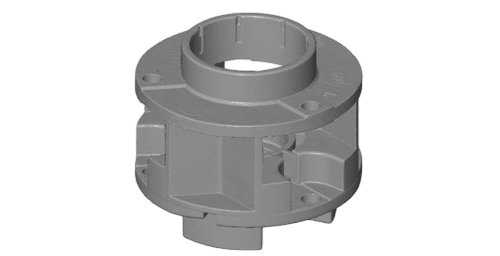

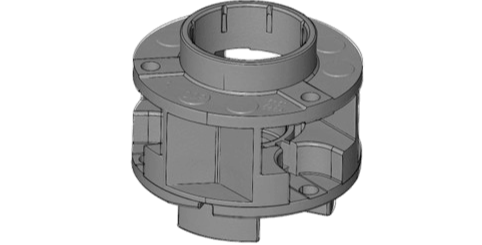

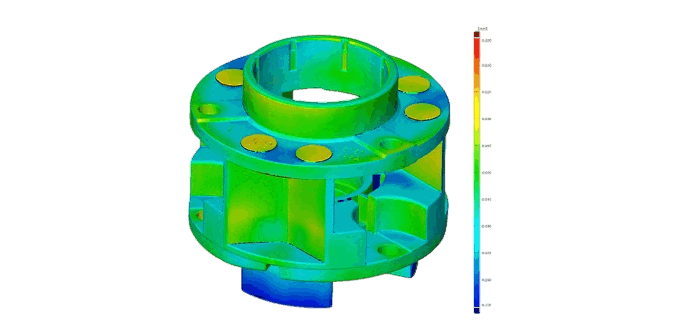

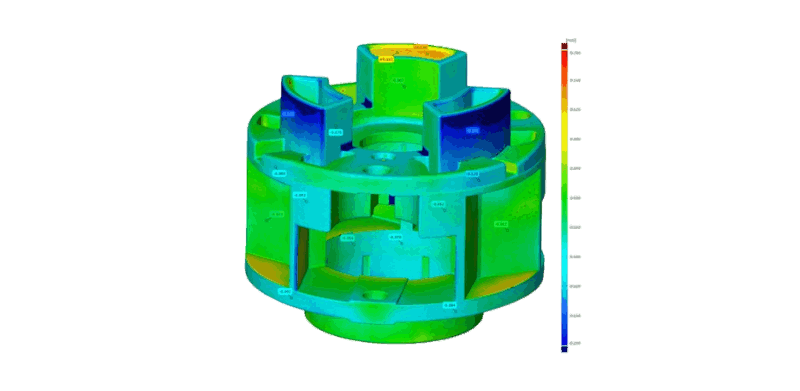

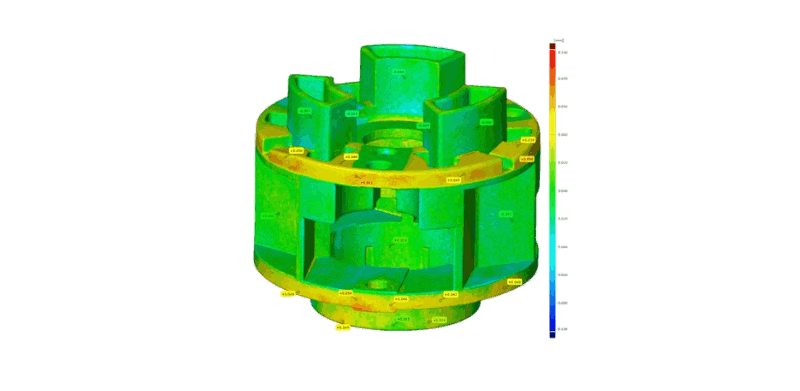

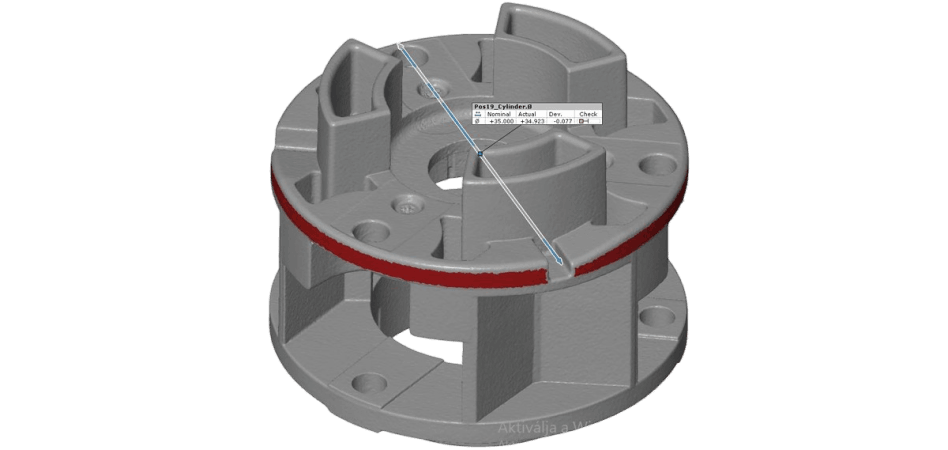

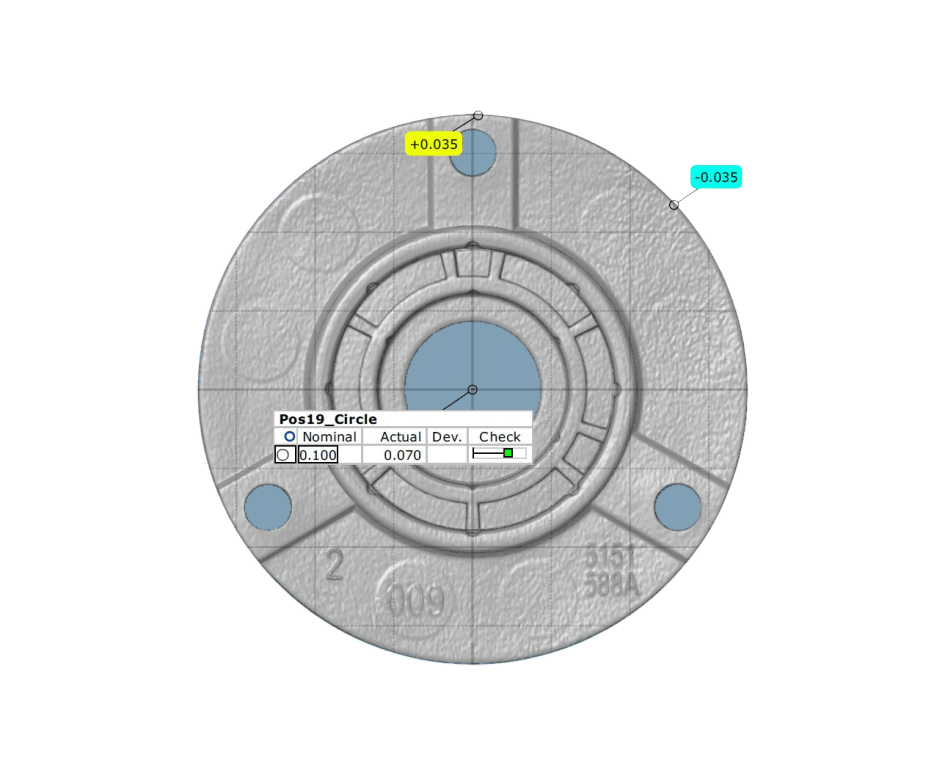

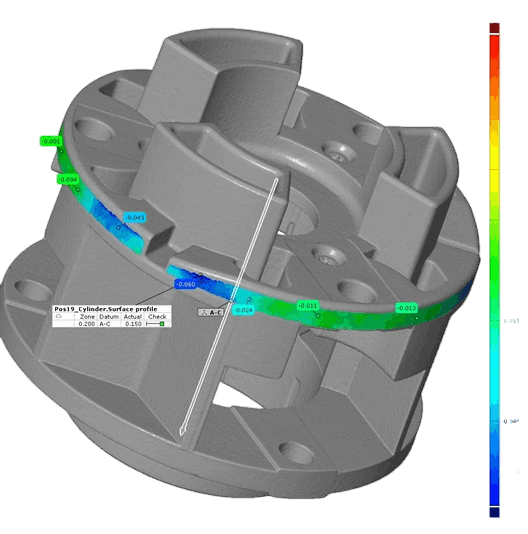

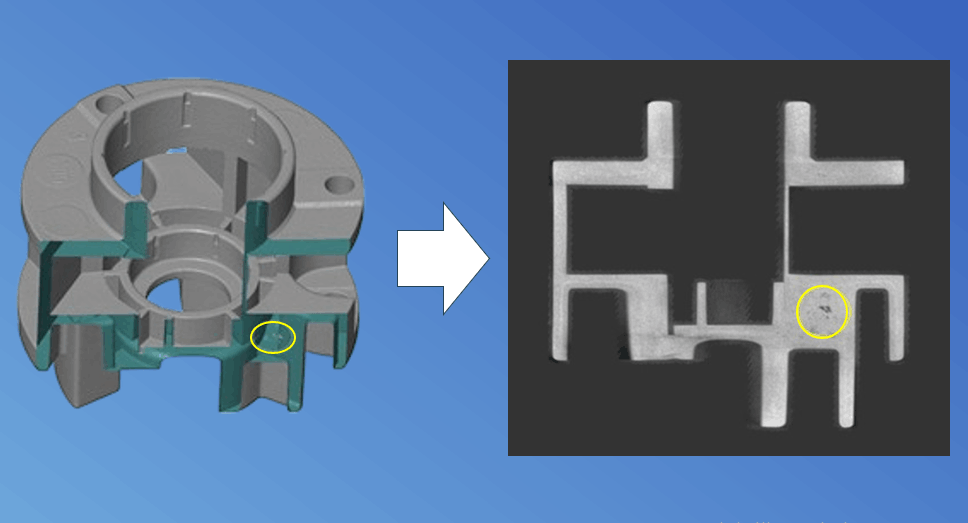

Siroma-Plast utilizes advanced CT technology to inspect both the internal and external structures of injection-molded parts. This capability plays a key role in quality assurance, product development, and tool optimization processes. Possible steps of a typical component analysed with this technology: