Feasibility Analysis & DFM

At the early stage of every new project, we conduct comprehensive feasibility analyses to ensure the manufacturability of future products. Our cross-functional team evaluates part design, material selection, and process requirements to identify risks and propose robust, cost-efficient solutions. As part of this, we provide Design for Manufacturing (DFM) input to optimize part designs for efficient and stable production.

Transfer Projects

Our experienced team takes full ownership of managing transfer projects, ensuring a seamless relocation of tools, processes, and know-how. We minimize production interruptions and safeguard quality and delivery performance during and after the transfer phase.

New tool management

We manage the complete tooling process in close cooperation with our toolmaking partners-primarily based in Europe, but also including Chinese suppliers for optimized lead times and flexibility.

From tool design validation to PPAP/EMPB sampling and approval, our project managers ensure a smooth, transparent workflow that meets quality, timing, and budget expectations.

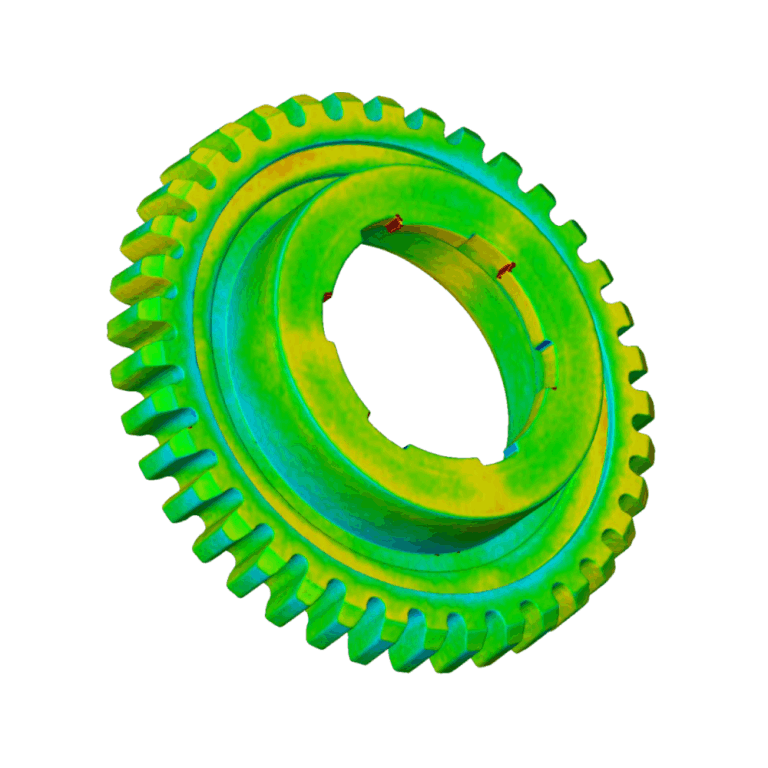

CT-based product optimisation

Using our in-house CT scanning capabilities, we support precise tool and product optimization during project phases. This advanced measurement technology enables us to identify deviations early and implement data-driven improvements, reducing development loops and accelerating project timelines.