Tampo printing

Our tampo printing capabilities cover both fully automated and flexible manual operations. We operate a customer-owned automated tampo printing line, ensuring consistent, high-volume output. Additionally, our in-house Teca machines allow for more customized, manual tampo printing, where we can achieve double or triple prints for enhanced surface quality and visual effect.

Assembly

Our assembly operations cover a wide range of processes, from simple manual component assembly to semi-automated tasks such as O-ring fitting and closed mounting stations where operators only feed the components. In addition various product decorating technologies are also performed in-house, including tampo printing, laser marking, and hot foil stamping. These capabilities allow us to offer flexible, integrated solutions that meet diverse customer and product requirements.

Hot Foil Stamping

Numbering of counting gears is one of our longest-standing areas of expertise, as this product group has been part of our portfolio since the company's foundation. We operate several automated systems where numbers or other customized markings are printed directly onto the gears produced in our injection molding hall, ensuring precision, durability, and efficiency.

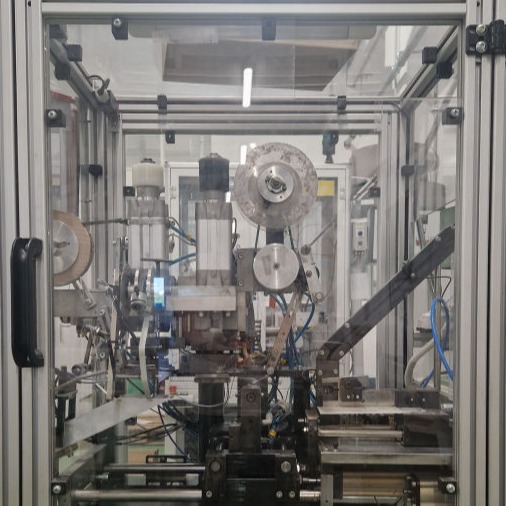

Automated assembly

On machines developed either by Siroma-Plast or by our customers, we perform various high-volume assembly operations. In these processes, the plastic components molded in-house are assembled with purchased parts such as screws, springs, and other components. Most of these assemblies are subject to integrated camera inspection or other quality control gates, ensuring reliable, consistent output even in complex processes.

Ultrasonic welding

Ultrasonic welding is one of the key technologies we use to create permanent adhesion between plastic components. Siroma-Plast operates both a manually operated ultrasonic welding unit and a CNC-programmable, high-precision system from Herrmann, which provides full traceability for every single welding cycle.

Upon request, we develop the necessary sonotrodes in cooperation with our specialized suppliers, ensuring optimal welding performance and product quality.

Laser printing

Laser printing serves as a faster and often more economical alternative to tampo printing in many applications. In 2024, we introduced our first fully automated laser printing machine, originally developed by a supplier of Schneider. This technology enhances our decorating flexibility and allows for durable, high-speed marking directly on molded parts.